How should the Hydraulic Brake Choose the Right Hydraulic Pump?

As a Hydraulic Brake Caliper Manufacturer, share with you. Gear hydraulic

pump, referred to as gear pump, is a kind of quantitative pump commonly used in

hydraulic systems of hydraulic brakes. It has the characteristics of simple

structure, reliable work, small size, light weight, low cost, convenient use and

maintenance. In addition, the gear pump also has the advantages of good

self-priming performance, large speed range, low requirements for oil filtration

accuracy, and insensitivity to oil pollution. The main disadvantages of gear

pumps are large flow and pressure pulsations, non-adjustable displacement, and

large noise.

Gear pumps can be divided into internal gear pumps and external gear pumps according to their meshing forms. Internal gear pump has compact structure, stable operation, low noise, good high-speed performance, small flow pulsation, but complex processing and low volume efficiency at high pressure and low speed. The process of external gear pump is simple. At present, more applications of hydraulic brakes are gear pumps with external meshing involute straight teeth.

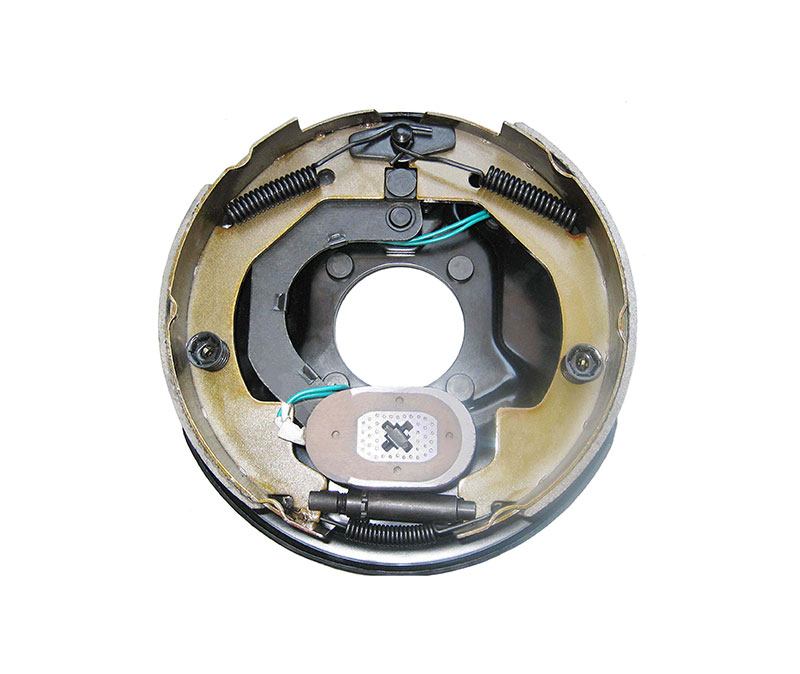

Trailer Disc Brake

When selecting Trailer Hydraulic Brake and hydraulic pump for the hydraulic system of the main engine, firstly meet the requirements of the main engine on its hydraulic system, such as flow, working pressure, etc., and then carry out performance, use and maintenance of the pump according to the characteristics of the main engine. Considering. When selecting the type of pump, the pump must have a certain pressure reserve. Generally, the rated pressure of the pump should be slightly higher than the system pressure. If the hydraulic system uses a single pump system (one pump supplies oil to several working circuits at the same time or at intervals), the pump The pressure should be selected according to the working pressure required for the high working circuit.

In the hydraulic system, the hydraulic pump of the hydraulic brake is usually driven by an engine or an electric motor. When the pump's operating speed is selected, it is required to work at its rated speed so that its working efficiency can be fully exerted. At the same time, the operating speed of the pump cannot exceed the high speed specified by the pump. If the speed of the pump is too high, it will cause insufficient oil intake, reduce the life of the pump, and even damage the pump in advance. In addition, because the oil supply of the pump depends on the displacement and speed of the pump, in a single pump system, when the pump is selected, if the working circuits do not work at the same time, the hydraulic pump with the required flow rate is selected. When several working circuits work at the same time (including or not including circuits with large required flow), when the required flow exceeds the required large flow, the hydraulic pump should be selected according to the flow. In order to reasonably select hydraulic brakes and hydraulic pumps in practical applications, the performance and application of various types of hydraulic brakes and hydraulic pumps are now compared.

Our company also has Trailer Disc Brake on sale, welcome to consult.

Previous None