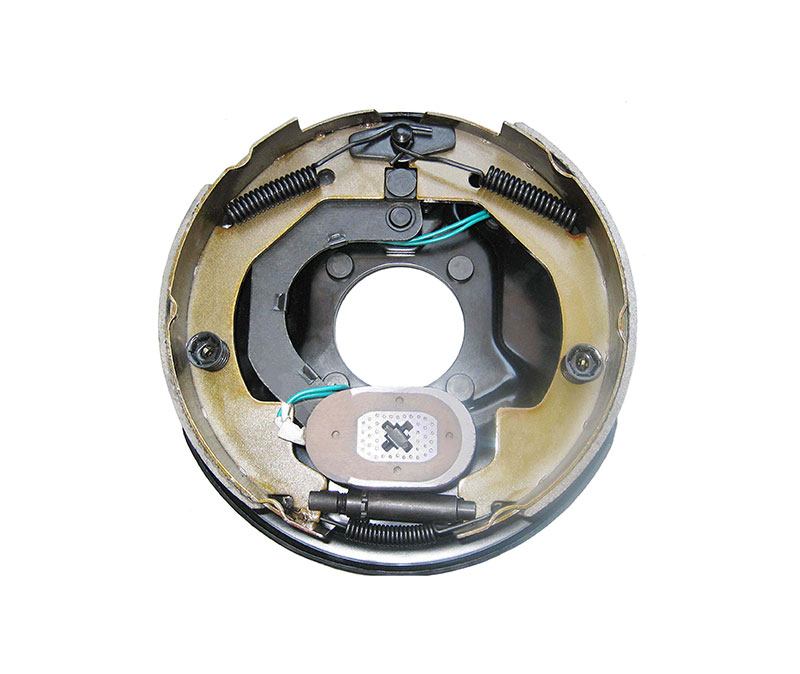

Installation Notes for Electric Drum Brake

As a Trailer Electric Brake Supplier, let us introduce the installation precautions for the brake drum.

1. In order to ensure maximum safety and reliability, it is recommended that you always check the Electric Drum Brake bearing regardless of the length of the car - pay attention to the early warning signal of the bearing wear: including any friction noise or suspension combination wheel Unnormal deceleration during a turn.

2. If you hear the noise from the bearing parts of Electric Drum Brake, first of all, it is important to find the location where the noise occurs. There are many moving parts that may produce noise, or some rotating parts may come into contact with the non-rotating parts. It is the noise in the bearing, the bearing may be damaged and needs to be replaced.

China Electric Drum Brake

3. Because the front brake drum causes similar working conditions on both sides of the bearing failure, even if only one bearing is broken, it is recommended to replace it in pairs.

4. China Electric Drum Brake bearings are sensitive, in any case, need to use the correct method and the right tools. During the storage and installation process, the bearing components can not be damaged. Some bearings require a large pressure to press, Therefore, special tools are required. Be sure to refer to the automobile manufacturing manual.

5. When installing the bearing, it should be in a clean and tidy environment. Fine particles entering the bearing will also shorten the service life of the bearing. It is very important to keep the environment clean when replacing the bearing. Do not use the hammer to strike the bearing, pay attention to the bearing not to fall. On the ground (or similarly handled improperly).