Where does Trailer Electric Drum Brake help in driving a car?

When the car is traveling, it wants to play a braking role, relying on an

external force opposite to the direction of the car and the external force is

randomly and uncontrollable, so the car needs to be equipped with

Trailer Electric Drum Brake.

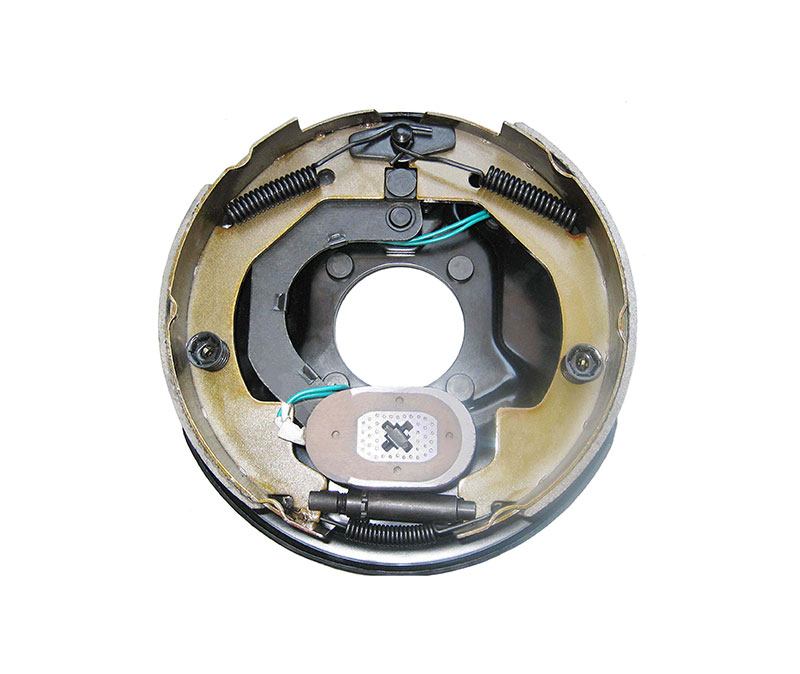

Trailer Electric Drum Brake

A car braking system refers to the installation of a special braking mechanism on the car in order to technically ensure the safe driving of the car and increase the average speed of the car. Generally, the braking system includes two sets of independent devices: driving brake device and parking brake device. The service brake is operated by the driver's foot, and the parking brake device is operated by the hand.

The function of the service brake is to slow down a moving car or stop it within a short distance. The function of the parking brake is to keep cars that have been parked on various roads. However, sometimes in emergency situations, two types of braking devices can be used simultaneously to increase the effect of automobile braking.

The principle of automobile brakes is to increase the friction between the fixed components and the rotating work surface, so as to achieve the braking effect. After the above analysis, do you know more about car brakes? As an Electric Drum Brake Wholesaler, share the relevant information with everyone.

Regardless of whether it is a car or mechanical equipment, in the work, you need to use a brake, which is often referred to as the brake device. We know that moving objects without brakes can be very dangerous. There are many types of brakes, such as drum brakes, Trailer Electric Brake, etc., depending on where they are used. What is the difference between these two braking methods?

1. For drum brakes, two semi-circular brake pads are installed in the wheel hub, and the "brake principle" is used to make the brake pads contact the inner surface of the drum to cause friction and brake. Disc brakes use brake calipers to control two brake pads to clamp the brake discs on the wheels. When the disc is clamped by the disc, friction occurs between the two.

2. The brake system of the drum brake can use lower oil pressure. The diameter of the drum brake will increase after heating, and the brake response will not be as expected. The disc brake has better heat dissipation performance than the drum brake, and it will not cause the brake to decline and make the brake fail when the brake is continuously stepped on. Disc brakes have relatively even braking power on the left and right wheels. The brake discs have better drainage and can reduce the phenomenon of poor braking caused by water or sediment.

3. The handbrake mechanism of the drum brake is easy to install. Some of the rear wheels are equipped with disc brakes, and the other is the drum handbrake installed at the center of the brake disc. The brake pedaling force is not well controlled, which is not conducive to rapid braking. The friction area between the disc brake pad and the brake disc is smaller than that of the drum brake, so the braking force is weak. To improve the shortcomings of the braking force, a larger stepping force or increased oil pressure is required to improve the brake power.

4. The processing of drum brake parts is relatively simple and the manufacturing cost is low, but there are many structural parts. The disc brake has a simple structure and is easier to maintain, but the brake pads are worn out and replaced frequently.