The use points and taboo of Trailer Brake Caliper

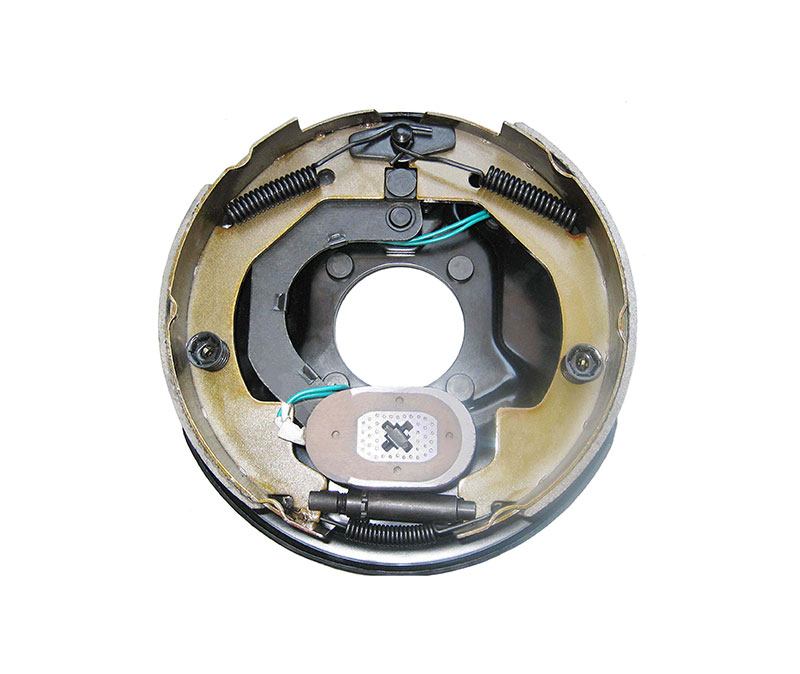

Brakes are an important part of motor vehicles. They are usually used to mount on the axles to match the wheels. Most of the trailer brakes are currently Trailer Drum Brakes, which include the mounting bracket and two opposite brake shoes. A friction plate is disposed on the outer edge surface of the shoe, one end of the brake shoe is a pivot end that is pivotally engaged with the pin on the mounting frame, and the other end is a free end that cooperates with the brake driving cam, and the brake driving cam is disposed on the two brakes. Between the free ends of the hoof, when the brake is actuated, the brake drives the cam to rotate, driving the two brake shoes to rotate around the pin shaft, which in turn causes the brake to form an outwardly expanding deformation tendency, the friction plate on the outer periphery of the brake shoe and the wheel mounted on the wheel The inner edge of the upper brake drum contacts and generates a large frictional force to reduce the rotation speed of the wheel relative to the axle to achieve the purpose of braking and braking. In addition, in order to realize the reset of the two brake shoes, it is also necessary to provide a return spring. The two ends of the return spring are respectively attached to the free ends of the two brake shoes. After the brake is completed, the brake shoe cam is reset, relying on the elasticity of the return spring. The stress pulls the two brake shoes back to their original position.

Trailer Brake Caliper

Normally, it is necessary to ensure that the brake shoe cam has a sufficient radius of rotation so that the brake shoe can be in contact with the brake drum after being rotated about its rotating end, so as to ensure the radius of rotation of the brake shoe cam, The distance between the brake shoe cam and the mounting bracket is very limited. If the return spring is installed within the spacing, it is easy to cause the return spring to interfere with the brake shoe cam and the mounting bracket.

Trailer Brake Caliper is also known as disc brakes. The main components are brake discs, brake pads, brake cylinders, brake calipers, etc. The brake disc is locked with the hub by bolts, and the brake cylinder is fixed on the brake base plate, and the two brake pads on the brake caliper are respectively mounted on both sides of the brake disc. When braking, the sub-pump pushes the brake pad to squeeze the brake disc to form a friction brake under the action of the brake air pressure. There are also many taboos and points of use when used.

1. The disc brake axle is not allowed to be water-cooled. Because the brake disc at high temperatures is exposed to water, it is likely to crack or even break, which will seriously affect the safety of the vehicle.

2. The tires, wheels, suspension system, brake system, etc. need to be inspected before the vehicle is running. Do a good job of daily use testing, find problems in a timely manner, and reduce security risks.

3. Every two weeks or frosty days, you need to open the drain valve at the bottom of the air reservoir to drain the water to ensure that the brake system air circuit will not be blocked.

Inspection and maintenance of disc brake axles

In addition to paying attention to the use of points, card friends also need to repeat the inspection of the brake system on a regular basis according to the frequency of their own brakes. For example, if the vehicle is often driving on a mountain road, a long slope, or having frequent braking habits, then it is necessary to increase the frequency of inspections. In order to avoid damage to the brake discs and brake calipers, BPW experts also gave some standard data, which must be replaced before the friction material wears anywhere to 2mm. If the friction plate is found to be burnt, cracked, polished, and contaminated by oil, it must be replaced immediately to prevent the brake system from malfunctioning. Emphasize that when replacing disc brake components, try to choose the well-known brand of Hydraulic Disc Brake Caliper Supplier or original accessories. Inferior brake pads and brake discs may wear out quickly, or even brake system due to insufficient brake friction. Failure.

When doing professional maintenance, remember to check the axles, such as grease the axles every year or after each replacement of the brake discs. If you feel that the axle is troublesome every time, you can choose BPW’s disc brake axle with BPW-specific lubricant for longer maintenance and better stability.

Disc brakes will soon be widely available, and only know how to match the main trailer to maximize the benefits of disc brakes. Of course, routine maintenance and inspection is an indispensable process. Once the brake system is found to be abnormal, it must be checked and replaced in time. Only in this way can the safety accident be minimized.