What does the wear of Trailer Disc Brake have to do with it?

Friction is a process that must occur when the Trailer Disc

Brake is running. During the friction of the brake linings and couplings of the brake, the outer layer of raw materials will be lost and transferred due to mutual reaction, which will cause wear. This will gradually increase the gap between the brakes until the lining and drum can no longer be used, which is the working life of the brake.

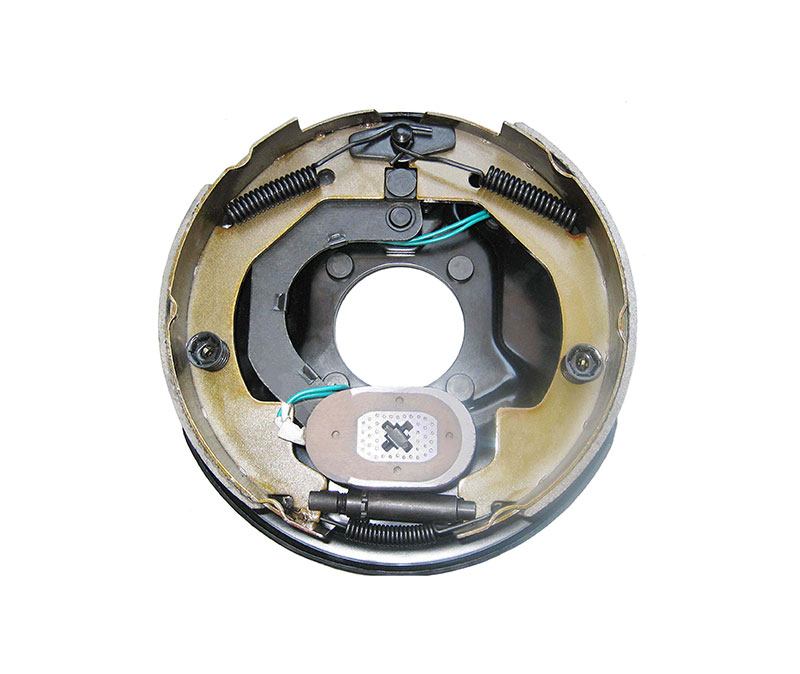

Trailer Disc Brake

From the perspective of the reliability of the brake, the friction index of the brake is very high, especially at high temperatures, it can still maintain a large friction index, that is, there is sufficient braking friction torque, but generally, the more the friction index The greater the friction, the higher the resistance generated by the friction, and the greater the shear stress on the outside. Therefore, the loss or damage of the raw material on the friction the surface will be more severe, the more abrasion will occur, and the working life will also be greater. The shorter, so friction and wear are two related and contradictory aspects during the friction period. Different working environments and conditions will have a different emphasis, but for the brake, some frictional resistance is required but it will not cause a relatively large amount of friction. The wear, brake wear and friction state during friction are related, and they vary with the working environment and the raw materials of the brake.

Because of its existence, emergency braking can keep people in a safe state because of its existence. The brakes are divided into many types according to different scenes, and the material of each different brake is also different. Brakes are used in many industries and are loved by many manufacturers. Many brake manufacturers are producing brakes.

Today the Trailer Galvanized Electric Brake Supplier will give you the advantages of popularizing disc brakes:

1. The thermal expansion of the brake disc will not cause the stroke loss of the brake pedal like the thermal expansion of the brake drum, which will also simplify the design of the automatic gap adjustment device.

2. Good thermal stability. Because the size of the brake friction pad is not long, the area of its working surface is only 12% ~ 6% of the area of the brake disc, so the heat dissipation is better.

3. The braking torque has nothing to do with the forward and backward driving of the car.

4. The disc-type friction lining is easier to replace after wear than the drum-type friction lining, the structure is simpler, and the maintenance is easier.

5. Disc brakes are the most popular makers in recent years, and their stability and heat resistance are higher than ordinary brakes. Of course, the cost is also relatively high, but nothing is more precious than life. It does not matter if the brakes are more expensive.

Our company also has Trailer Cast Iron Brake Calipers on sale, welcome to consult.