What Causes the Brake Scraping Noise?

Trailer Drum Brakes are achieved by pressing the brake pads on the brake wheels. Drum brake is an early-designed braking system. The design of its brake drum has been used in carriages since 1902, and it was not widely used in the automotive industry until around 1920. The mainstream of the drum brake is the internal tension type. Its brake pads (brake shoes) are located on the inner side of the brake wheel. When the brake is applied, the brake pads open outward and rub the inner side of the brake wheel to achieve the purpose of braking. In the past three decades, drum brakes have gradually withdrew from disc brakes in the field of passenger cars. However, due to the relatively low cost, it is still used in some economic cars, mainly for rear wheels and parking brakes with relatively small braking loads. As an Electric Drum Brake Wholesaler, let everyone know.

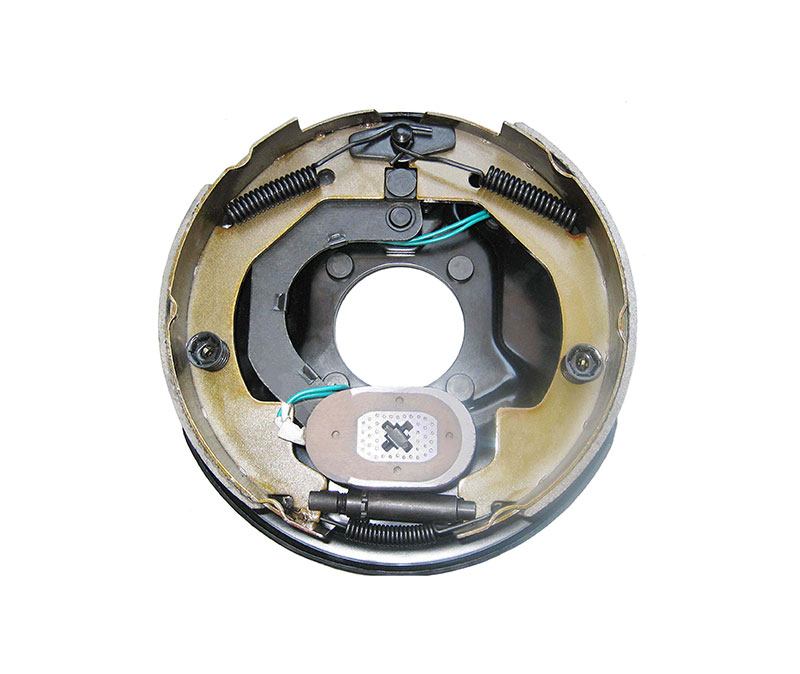

Electric Drum Brake

1. The friction plate is damaged

If the rivet head of the riveted friction plate is worn or the material of the bonded friction plate fails, the friction plate can fall off, then the metal will directly contact during braking, and the rotor will be scratched by metal particles. They not only affect the safe braking distance, but also cause great damage to the relay surface. In order to eliminate the above faults, the new friction plate should be replaced first, and then the damaged rotor surface should be repaired.

2. Brake caliper misalignment

When the caliper is misaligned, the brake disc may be scratched by metal particles. Every part must be checked carefully during maintenance. If any damaged or worn parts are found, they should be replaced in time. It should also be replaced if the caliper mounting ear holes are uneven, severely damaged, and the guide surface is worn.

3.The edges of the caliper and brake disc are rusty and stained

If these problems are found during inspection, the relevant parts must be cleaned and derusted. If the rusted surface has affected the normal operation of the brake caliper and brake disc, they must be replaced.

4. Loose bearing ring

If the bearing ring is found to be loose, repair and necessary adjustments should be made.

Adjustment method of brake gap:

1. Automatic adjustment

The automatic adjustment brake automatically adjusts the gap. When the parking brake or foot brake is executed, the automatic clearance adjustment device works, and the brake clearance is adjusted by the adjustment lever.

2. Manual adjustment

Turn the brake gap adjuster to adjust the outer diameter of the brake shoes to be approximately 1mm smaller than the inner diameter of the brake drum. The specific operation method is as follows: Use a screwdriver to turn the adjusting nut, expand the brake shoe outwards until the brake drum is locked, and then return the adjusting nut to the specified number of slots.

Our company also has Electric Drum Brake on sale, welcome to consult.