What should I do if the Brake is Noisy?

As a Trailer Galvanized Electric Brake Supplier, share with you.

What is a brake? In fact, a brake is what we call a brake. Of course, brakes are used in a wide range of applications. Generally, movable mechanical equipment is applied to brakes. There are many types of brakes, including one. One is that people who have used Trailer Electric Brake may encounter noise from disc brakes. What should I do?

First: Add a noise prevention plate between the piston of the brake caliper body and the brake lining, so that a tilt is formed on the piston. Then make sure that the brake pads and flexible touch when braking, so that the brake pads show no abnormal noise under normal wear and tear.

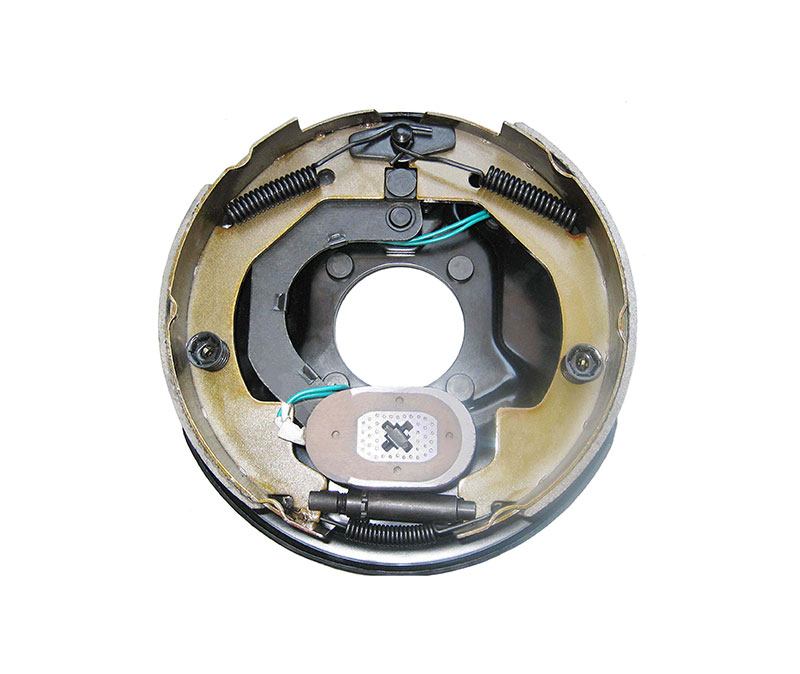

Electric Drum Brake

Twenty-two: When the disc brake is braked, the brake pads move to one side, which can show impact and movement. This is because the gap between the brake pad and the caliper body is too large. The gap can be eliminated by plating with solder. However, it should be noted that the solder plating should be on the side opposite to the direction of travel to avoid failure under the effect of braking force.

Thirty-three: Select brake pad materials that are softer and less dense for the brake.

To sum up, it is the method to deal with the brake arc noise. Seeing this, are you clear about this? And we can take corresponding measures according to the specific situation to avoid other problems!

When the brake motor is powered on, the motor and the warp ring of the brake are energized together. At this moment, the magnet disc of the brake overcomes the pressure of the tension spring and is attracted to the side of the magnetic pole group.

When the power supply is cut off, the magnet disc is pushed out by the tension spring because the magnetic field is not visible, causing the conflict disc on the magnet disc to collide with the brake plate and quickly brake the motor.

Someone will ask the role of the brake and clutch on the motor.

The brake is parked immediately after the electric motor is powered off, so that the machine stops in the position where it should be stopped, without too much wrong stroke. There are several types of clutches, such as separate clutches, which can separate some of the automatic shifting machinery from the shifting machinery. When the operation is required, the clutch can be closed to operate. Hazard to the motor. The other is overrunning clutch. It is a mechanical protection device. When some machinery is overloaded, the overrunning clutch will slip, so that it will not cause excessive damage to the machine.

Our company also has Electric Drum Brake on sale, welcome to consult.