Why does the Brake stop working again?

The brake is a necessary part of the machine, and its main function is to control the operation of the machine. A common application in life is automotive equipment. The brake is a kind of equipment that we often see in our life and production. This kind of equipment can stop or decelerate a motor vehicle very well, so the role of the brake on the motor vehicle is very obvious and very important, especially the key to the brake Role, so many brake manufacturers on the market, these manufacturers produce brakes with different performances, and different scenarios. Therefore, when you choose, you need to screen.

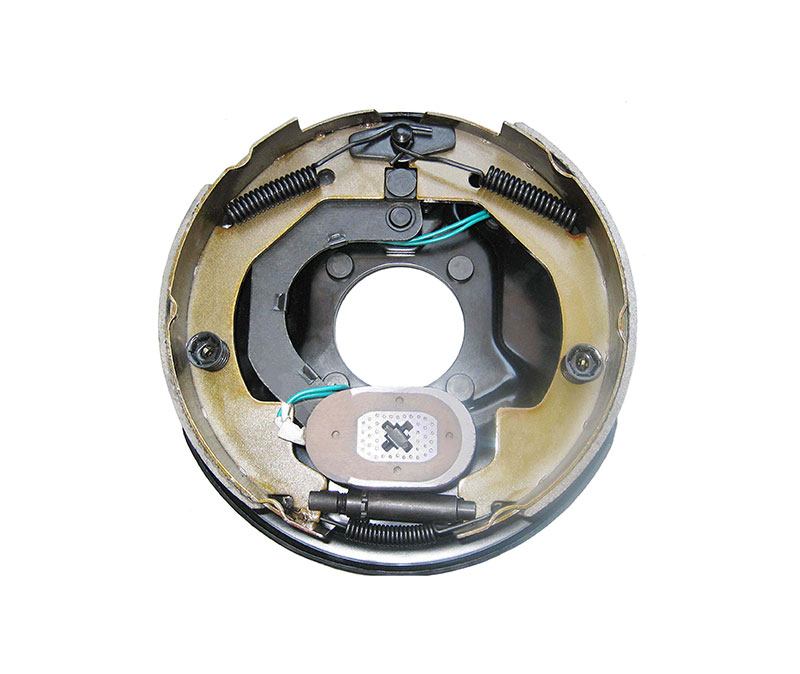

The brake has the advantages of simple structure, wide adaptability, low noise and reliable braking. Among them, the hydraulic brake has a very large effect on each vehicle. Understanding the working principle of the hydraulic brake can better drive the vehicle. Good hydraulic brakes can quickly stop the car and reduce wear. The hydraulic brake device is composed of a brake pedal, a brake master cylinder, a brake wheel cylinder, a wheel brake, a brake roller, and a pipeline. When the brake pedal is depressed, the piston pushes the master cylinder forward. However, some people report that Electric Drum Brake brakes often fail as the machine is used longer. This is a particularly dangerous thing. Why is this happening? After research, it is probably due to the following two reasons:

Electric Drum Brake

(1) Improper adjustment of the control mechanism. After the braking force is applied, the brake cam of the drum brake does not rotate in place, and the opening angle of the brake shoe is not large enough to press the friction plate against the inner surface of the brake drum, causing brake failure.

(2) The friction plate is worn. Because the brake is used for a long time, especially during the continuous downhill, the surface temperature of the friction plate will rise, and ablation, aging or severe wear will occur, which will greatly reduce the friction coefficient and affect the braking performance.

Electric Drum Brake Wholesaler reminds you again that after the brake malfunctions, you must check and repair in time.

Why does the brake respond slowly? There are probably the following aspects:

(1) The pedal is too far away.

(2) There is too little brake fluid in the master cylinder, or the holes are blocked by impurities, and the master cylinder parts are swelled and even deformed or stepped over.

(3) The brake master cylinder parts are so worn that they cause loose oil leakage, the oil return valve is not sealed well, and the tension spring of the oil outlet valve is broken.

(4) The brake pump parts are swelled and swollen, and the pistons are blocked, and the live parts of the pump are severely worn, causing loose connections and oil leakage.

(5) The brake shoe wears a lot, the brake clearance is large or the clearance is not installed well.

(6) The brake drum is not round, causing grooving or abrasion, the outside of the brake shoe is stained with oil, the burnt becomes very hard, and the rivets are relatively obvious.

(7) There is oxygen in the brake system or the temperature inside the brake is too high, and the brake fluid in the pipeline is vaporized, causing air blocking.

(8) The tubing is not round, the connection is not tight, the oil leaks, the hose is aging, broken or blocked by impurities.

Our company also has Trailer Electric Brake for sale, welcome to consult.